Groundbreaking New Reports Reveal Massive Environmental Benefits, Cost-Competitiveness of Cultivated Meat

If renewable energy is used in its production, growing meat directly from cells is likely to compete on costs and have a lower environmental footprint compared to conventional meat production in under 10 years, according to a new pair of studies analyzing the life cycle and techno-economics of commercial-scale cultivated meat production.

These newly released reports, a life cycle assessment (LCA) and techno-economic assessment (TEA), are the first ever reports to be informed by data contributed by companies involved in the cultivated meat supply chain. Over 15 companies and one government scientific body (from Singapore) participated, including five cultivated meat manufacturers. The studies used industry data to model how cultivated meat may be produced by the year 2030 and assessed the costs and environmental impacts of a commercial-scale facility that produces 10,000 metric tons of a ground cultivated meat product per year.

“These reports show—using real-world data from companies operating today—that cultivated meat can help governments in Asia Pacific fulfill net-zero emission pledges, while also enhancing food security and creating new high-paying job opportunities. Singapore’s bold efforts to accelerate alternative proteins at every stage from R&D to regulation and distribution have created a model for success, but global issues require global solutions, so it’s time for other governments around the region to wake up and embrace this better way of making meat.”

– GFI APAC Acting Managing Director Mirte Gosker

Renewable energy is critical to realizing the full potential of cultivated meat

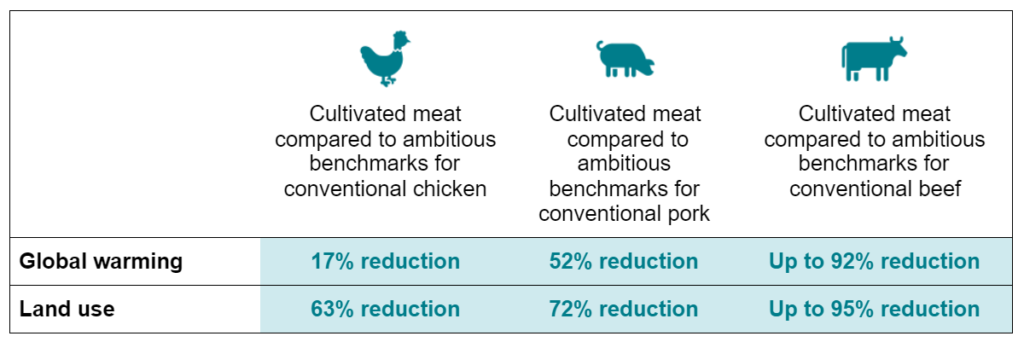

The LCA was the first study to analyze scenarios of cultivated meat production powered by an average conventional energy mix versus a renewable energy mix. If renewables are used, the carbon footprint of cultivated meat production drops by 80 percent. Even when compared to an extremely optimistic scenario projecting reduced environmental impacts of conventional animal agriculture (including renewable energy at farm and feed operations), cultivated meat produced using renewable energy reduces global warming impacts by 17 percent, 52 percent, and 85 to 92 percent compared to conventional chicken, pork, and beef production, respectively. These conclusions are expected to be highly robust, as the study also accounts for uncertainty in cultivated meat production by conservatively assuming high energy use at the facility, which is representative of an upper estimate.

Cultivated meat environmental impact comparison (when produced via renewable energy)

Similar gains are not expected in the conventional meat industry, where fossil fuels account for only approximately 20 percent of carbon emissions throughout the supply chain. Countries that aim to reduce their carbon footprint can thus achieve a greater rate of emissions reductions if they increasingly replace their meat sourcing or production with cultivated meat.

Benefits extend beyond carbon emissions

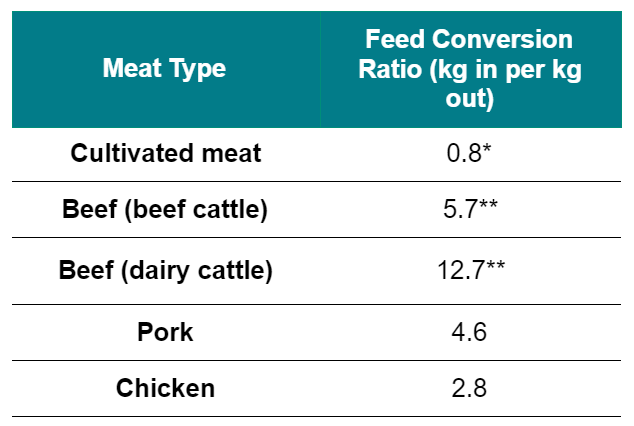

The LCA shows that cultivated meat is 3.5 times more efficient than conventional chicken (the most efficient form of conventional meat production) at converting feed into meat. As a consequence, cultivated meat production reduces land use by 63 to 95 percent compared to conventional meat. If this land is carefully repurposed to rebuild ecosystems and sequester carbon or simply grow more human-edible food, we can significantly offset carbon emissions (a benefit not incorporated into the LCA) and address global food security challenges.

In alignment with previous studies, cultivated meat is also expected to be less polluting (29 to 93 percent reduction) compared to all forms of conventional meat and use significantly less (51 to 78 percent reduction) blue water (found in surface and groundwater reservoirs) than conventional beef production (about the same as chicken and pork). Switching to cultivated meat could bring other positive benefits, including mitigation of antibiotic resistance, foodborne illness, and zoonotic disease risk associated with conventional animal agriculture, restoration of terrestrial and marine habitats, and a decreased rate of biodiversity loss.

Cultivated meat can compete on costs

The TEA found that cultivated meat can compete with some conventional meats on costs by 2030, with production costs in the study as low as $5.66 per kg ($2.57 per pound). Hybrid products that combine plant-based meats with cultivated meat as an ingredient offer a compelling near-term opportunity to further reduce costs and more thoroughly biomimic the meat-eating experience.

The model production facility has an estimated cost of $450 million USD, which decreases to $250 million USD with improved production efficiencies (this cost is included in the $5.66 per kg ($2.57 per pound) production cost estimate). However, to realize this competitive production cost by 2030, relaxed payback periods and a menu of financing strategies and incentives will be needed to lower the cost burden on cultivated meat manufacturers and install new infrastructure at high rates.

Importantly, new technological developments not featured in the study—such as specialized and automated cultivators for meat production, cell culture media recycling, and improved methods for growth factor production—are just a few ways to further reduce the costs of cultivated meat production.

A roadmap for success

These studies paint the most complete picture of the costs and environmental impacts of large-scale cultivated meat production to date. However, data gaps exist and assumptions may change as the nascent cultivated meat industry matures. The findings should not be taken as unchanging truths or as the absolute lower bounds of costs and environmental impacts of cultivated meat. Rather, the insights from the reports can be used to address technical and economic bottlenecks and serve as guidance for stakeholders to further the development and deployment of cultivated meat.

GFI has created the roadmap for entrepreneurs and scientists to address the technical challenges that will accelerate the industry and for stakeholders to capitalize on the potential for cultivated meat to mitigate massive global challenges related to climate change, antibiotic resistance, and other areas of human, animal, and planetary health.

About the study’s partners and roles:

The LCA study was commissioned by GFI and GAIA, who lent their expertise to assist in the research process and connect to data partners. CE Delft was independent in carrying out the analysis and writing the reports. Raw data from companies was not shared with GFI or GAIA. The TEA study was commissioned by GFI. All other project roles were the same as stated above. These reports were made possible thanks to the support of GFI’s donor family.